Menu

The Key to Industrial Water Purification Systems

- By Peter Wood

- June 16, 2025

- 5:01 am

In manufacturing and healthcare, industrial water purification systems are essential for operational efficiency and regulatory compliance. Contaminated water can damage equipment, increase maintenance costs, and lead to non-compliance with UK water discharge regulations, risking significant fines. Ion exchange media effectively removes harmful contaminants like ammonia and manganese, ensuring high-quality water output. This article explores how ion exchange media addresses compliance and equipment protection, aligning with the 2025 UK Sustainability Reporting Standards

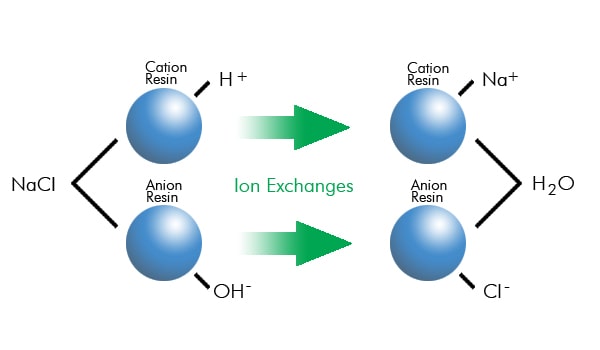

Ion exchange media consists of small, porous resin beads that remove unwanted ions such as calcium, magnesium, iron, and manganese by exchanging them with less harmful ions like sodium or hydrogen. These beads, typically 0.3–1.6 mm in diameter, are arranged in a resin bed. The media can be regenerated using a brine solution, allowing for repeated use and making it a cost-effective solution for continuous water purification. This technology is widely used in industrial water purification systems to ensure water meets stringent quality standards for applications like boiler feed water and pharmaceutical production.

Benefits for Manufacturing and Healthcare

Ion exchange media delivers key benefits for manufacturing and healthcare:

- Equipment Protection: By removing scale-forming ions, it prevents corrosion and extends equipment lifespan, reducing maintenance costs.

- Process Efficiency: Ensures high-purity water for consistent manufacturing output and safe healthcare applications.

- Sustainability: Supports water reuse, reducing environmental impact.

In manufacturing, ion exchange media prevents scale buildup in boilers and pipes, while in healthcare, it ensures contaminant-free water for pharmaceuticals, meeting strict regulatory standards.

Wychwood’s Tailored Solutions

Wychwood Water Systems designs bespoke water purification solutions using ion exchange media, customised based on client water analysis certificates. Their systems use reliable UK components and offer responsive maintenance services to minimise downtime.

Ensuring Compliance with UK SRS 2025

The 2025 UK Sustainability Reporting Standards (https://www.gov.uk/guidance/uk-sustainability-reporting-standards), expected to be finalised in Q1 2025, require businesses to report on water management. Ion exchange media ensures compliance by removing contaminants from discharge water, meeting Environment Agency standards. Wychwood’s systems support these goals and align with sustainability requirements.

Conclusion

Ion exchange media is critical for industrial water purification systems, ensuring compliance, equipment protection, and sustainability. Wychwood Water Systems’ tailored solutions help UK businesses meet regulatory standards and optimise operations. Contact Wychwood today to enhance your water compliance strategy.

Share on facebook

Facebook

Share on google

Google+

Share on twitter

Twitter

Share on linkedin

LinkedIn

Share on pinterest

Pinterest