Menu

Industrial Water Deionisation, Demineralisation & Ion Exchange

We provide, install and service deionisation products. Contact us for a quote or advice.

Also known as ion exchange or de-mineralisation, deionisation has been used in commercial settings for over 50 years. This well-known and proven technology uses cation and anion ion exchange resins to remove total dissolved solids (TDS) from the water.This technology has many applications and can be configured in many different formats to achieve 50 µS/cm to 0.055 µS/cm in water purity (0.02 to 18.2 MΩ-cm reciprocal).Contact us and ask our experts about the IONMASTER range if you believe that industrial water deionisation is what you do require.

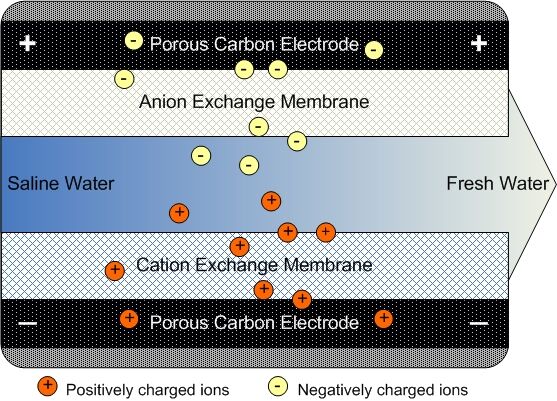

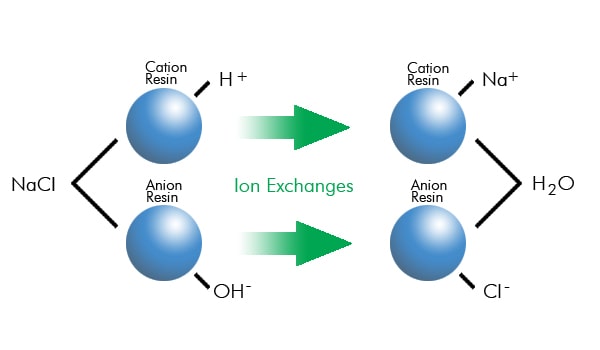

How Deionisation Works

The deionisation process uses cation and anion ion exchange resin beds to remove contaminants from water. Ions are attracted to the resin, becoming trapped on its surface and effectively removed from the water. The impurities are replaced by hydrogen (H+) and hydroxide (OH-) ions which are exchanged from the resins.

Resin Bed Types

There are many types of resins available for use in deionisation systems: single-use and rechargeable.Single-use resins will expire after the resin has reached its capacity for contaminants, which cannot be cleaned from the surface.Rechargeable resin can be used time and again. Regenerating the resin involves mobilising target contaminant ions by passing a regenerant solution over the resin. Acid, base or salt can also be involved in the regeneration process.Selective ION Exchange

Chilate resins are used for the removal of heavy metals. This is particularly effective in industrial effluent situations where heavy metals must be removed to bring the effluent into outfall compliance levels.

Advantages and Disadvantages

The industrial water deionisation process is an advantage because it wastes less water and has a lower capital cost than reverse osmosis. As stated previously, automatic ion exchange processes can be configured in many different formats to achieve 50 µS/cm to 0.055 µS/cm in water purity (0.02 to 18.2 MΩ-cm reciprocal).

The potential disadvantages of industrial water deionisation are the use and discharge of chemicals and the downtime of regenerations.

Download Our Complete Guide to Industrial Water Purification Systems

What Our Clients Think

“Having an old De-Alk plant we were in a position to upgrade and went out to tender. Wychwood Water were one of the companies to respond, organising a full site visit and answering all questions fully and in great detail. The knowledge from Wychwood was second to none and any questions we had were quickly answered. Everything from the tender response to install went smoothly without any issues. I would definitely recommend Wychwood Water if you are looking for a comprehensive, professional company.” Jonathan Patman

Is Deionisation Right For you?

Not sure if industrial water deionisation is the best fit for your application? We understand the challenges of choosing the correct system.

View our range of deionisation products or speak with one of our experienced team members via email or phone.

We look forward to assisting you!

Request a Consultation With a Water Expert

Wychwood Water needs the contact information you provide to us to contact you about our products and services. You may unsubscribe from these communications at anytime. For information on how to unsubscribe, as well as our privacy practices and commitment to protecting your privacy, check out our Privacy Policy.

Enquire Form Product

Unlock Pure Excellence in Water Treatment Today! Don’t let water quality concerns hold back your business. With our expert advice and cutting-edge solutions in commercial water treatment and filtration, achieving optimal water quality has never been easier. Dial us now for a personalised consultation and discover how our services can elevate your operations to new heights of efficiency and sustainability. Your journey towards crystal-clear, quality water begins with just one call. Reach out today